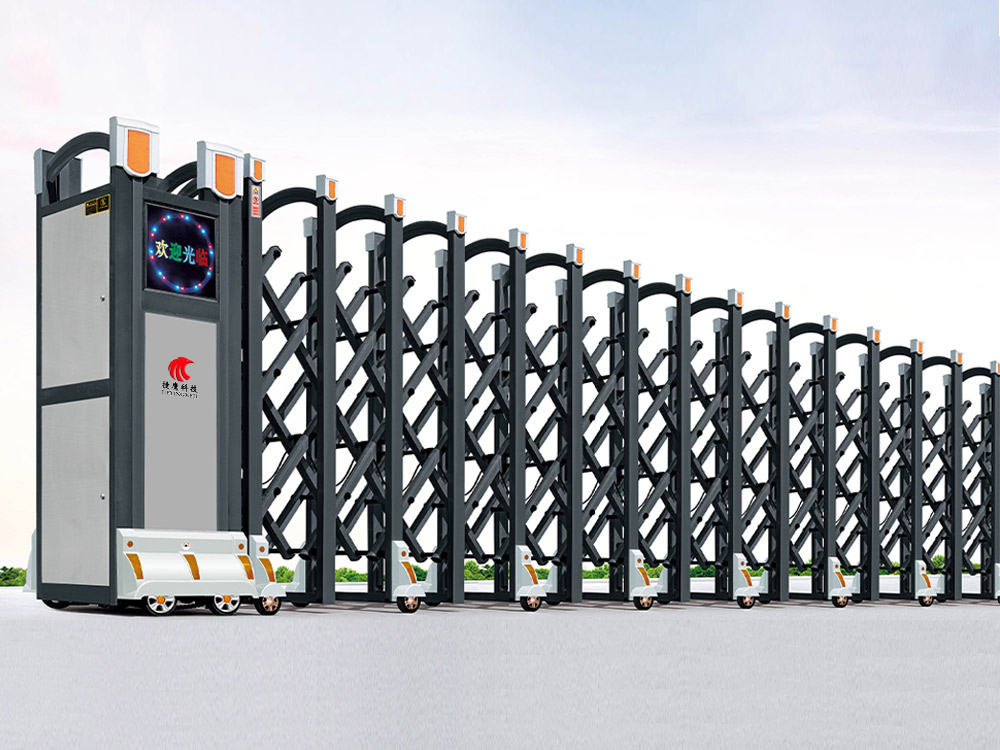

For stainless steel products, such as processed products such as electric doors, most people think that it will not rust. This is a relatively one-sided view. In addition to its own defects, stainless steel is corroded due to its environment, such as air humidity, air temperature, flow speed, flow direction, and the composition and quantity of impurities in the air. Big relationship.

1. The surface of stainless steel accumulates dust containing other metal elements or attachments of dissimilar metal particles. In humid air, the condensed water between the attachments and stainless steel connects the two into a micro battery, which initiates an electrochemical reaction , The protective film is damaged, which is called electrochemical corrosion.

2. Organic juice (such as food juice, saliva, etc.) adheres to the surface of stainless steel. In the presence of water and oxygen, it forms organic acid, which will corrode the metal surface for a long time.

3. In polluted air (atmosphere containing a lot of sulfides, oxides, and hydrogen oxides), contact with condensed water will form nitric acid and acetic acid liquid spots, causing chemical corrosion.

4. The surface of stainless steel adheres to acid, alkali, and salt substances (such as alkali water and lime water spray test on the decoration wall) causing local corrosion.

In summary, it will cause damage to the protective film on the surface of stainless steel and cause corrosion. Therefore, to ensure that the metal surface is bright and not rusted, we recommend:

① Regularly check the surface of the electric door, clean and scrub from time to time, remove attachments, and eliminate external factors that cause rust.

② For those areas where there is no industrial pollution, it is necessary to inform relevant personnel when installing stainless steel products and select the appropriate types of stainless steel materials, such as 201 and 202 materials.

③ 304 stainless steel should be used in coastal areas, which can resist seawater corrosion.

What should I do if the stainless steel has rust spots?

a) Chemical method:

Use pickling paste or spray to assist the re-passivation of the rusted parts to form a chromium oxide film to restore corrosion resistance. After pickling, in order to remove all contaminants and acid residues, it is very important to rinse with clean water. After all treatments, re-polishing with polishing equipment and sealing with polishing wax. For those with slight rust spots, you can also use a 1:1 gasoline and engine oil mixture to wipe off the rust spots with a clean cloth.

b) Mechanical method:

Sandblasting, blast cleaning with glass or ceramic particles, annihilation, brushing and polishing. It is possible to use mechanical methods to wipe off the pollution caused by the previously removed materials, polishing materials or oblique materials. All kinds of pollution, especially foreign iron particles, can become a source of corrosion, especially in humid environments. Therefore, mechanical cleaning of the surface is better and should be properly cleaned under dry conditions. The use of mechanical methods can only clean the surface, and cannot change the corrosion resistance of the material itself. Therefore, it is recommended to re-polishing with polishing equipment after mechanical cleaning and sealing with polishing wax.